✨ Why ASTM F136 Titanium Piercing Jewelry May Lose Gloss After Anodizing and Sterilization

ASTM F136 titanium piercing jewelry may lose its shine after anodizing and sterilization due to the following reasons:

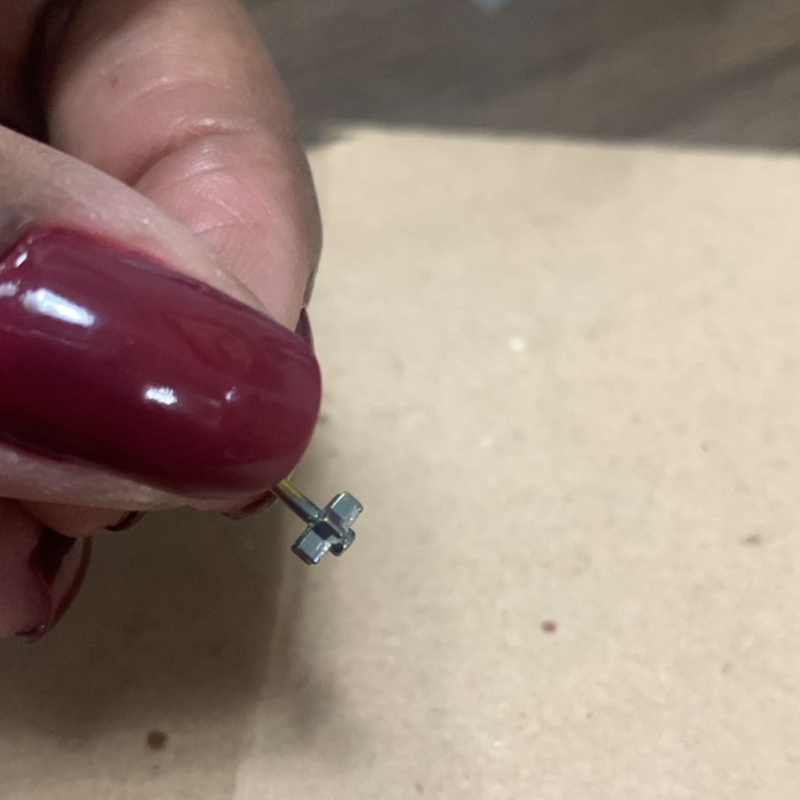

🔍 1. Improper Anodizing Process

- Excessive or Unstable Voltage:

When the anodizing voltage is too high or unstable, the surface color may become uneven or oversaturated, making the finish appear dull or grayish. - Contaminated or Improper Electrolyte Composition:

Impurities in the electrolyte solution can deposit on the jewelry surface, affecting smoothness and gloss. - Failure to Rinse or Neutralize Promptly After Anodizing:

If the remaining electrolyte is not thoroughly rinsed off or neutralized in time, it may corrode the surface or leave residues, leading to a loss of luster. - Inadequate Surface Preparation:

If the titanium surface is not properly polished or still has oil or dirt before anodizing, the resulting oxide layer may appear dull and lack gloss.

🔍 2. High Temperature or Improper Sterilization Methods

- High-Temperature Steam Sterilization (e.g., Autoclaving):

Colored anodized layers are sensitive to heat and may fade or darken under high-temperature environments, resulting in a gray or dull surface. - Use of Chlorine-Based or Strong Oxidizing Disinfectants (e.g., Bleach):

Chloride ions can corrode the titanium surface, making it rough and causing it to lose its shine.

🔍 3. Lack of Post-Anodizing Polishing or Sealing Treatment

If anodized titanium jewelry is not further polished or sealed, the oxide layer surface may remain rough and not reflective, leading to reduced overall gloss.

✅ Recommended Solutions

- Optimize Anodizing Parameters:

Standardize voltage, electrolyte concentration, and timing to ensure consistency and quality. - Rinse Immediately and Dry Thoroughly After Anodizing:

Use pure water to prevent residual electrolyte from corroding the surface. - Use Mild Sterilization Methods:

- Recommended: 70% isopropyl alcohol wiping or ultrasonic cleaning.

- Avoid: High-temperature steam and chlorine-based chemicals.

- Ensure Proper Pre-Anodizing Polishing:

Mechanical polishing quality directly affects the final gloss. - Apply Sealing Treatment:

Consider hot water sealing or similar processes after anodizing to enhance durability and shine.